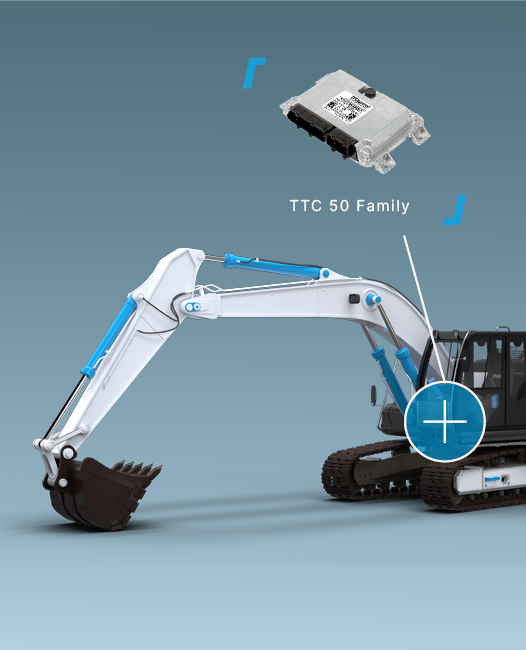

TTC 36X and the TTC 48X are both members of the TTC 50 family, which also includes the safety-certified I/O module TTC 48XS. The smaller TTC 36X offers 24 inputs and 16 outputs, while the bigger TTC 48X provides 28 inputs and 20 outputs. (See detailed overview here.)

The I/O modules are:

- CANopen-based

- cost effective

- modular

- and user-friendly

With these solutions you can easily extend the number of I/Os in mobile applications. The controllers are best suited for different kinds of control tasks in a vehicle and acts as device units in a CAN-based network architecture.

I/O Module Datasheets

Increase Cost and Time Efficiency

The intelligent I/O device modules TTC 36X and TTC 48X can be used in combination with, and controlled by a controller electronic control unit. The controller control unit can be located at an entirely different place in the vehicle and communicates with the device module via the standardized CANopen protocol.

One or more TTC 36X or TTC 48X can be used in addition to the controller control unit in a modular way. This distributed architecture makes the design and assembly of different vehicle variants possible and more cost and time effective. In addition cabling is simplified and more economic.

TTC 36X and TTC 48X are delivered with a ready-to-run software. The application has to be implemented for the controller only and interfaces with the device module via CANopen. This makes the setup user friendly and saves development time.

Local current control on the PWM outputs of the TTC 36X and TTC 48X allow efficient control loops on the device module. The dither frequency for the valves can also be individually configured.

Key Benefits

- Easy integration and usage

- CANopen compliant

- Automotive style housing suited for rough operating conditions