Machine manufacturers today are facing complex challenges: While market dynamics call for faster development and a shorter time to market, mobile machinery has to meet extensive safety standards that apply not only to individual components but to all safety-relevant functions for machine control systems. The additional expenses caused by this cannot simply be shifted to the customers by increasing the machinery prices.

This is where the “Machine Application Tool Chain – MATCH” comes in. MATCH Software Suite is a cutting-edge platform by HYDAC Software that serves as one robust system for all your software requirements. Offering a holistic solution for the entire product life cycle, MATCH is an innovative, efficient, and TÜV-certified solution, ensuring top-notch performance and reliability.

The cutting-edge platform offers seamless solutions spanning the entire machine lifecycle and accelerates the realization of important safety functions. Machine manufacturers have the ability to swiftly develop and realize new applications for complex vehicle or machine controls.

With MATCH, you can rapidly design and realize new applications for complex vehicle or machine controls, but also quickly redesign existing machines, machine parts and functions. MATCH enables time savings of up to 50%.

The main highlight: embedded safety standards. With MATCH, you can incorporate aspects of functional safety into the development of your control systems from the outset. All safety-relevant modules are TÜV-certified. This makes your control systems future-proof.

The MATCH tool chain is made up of optimally coordinated tools. The consistent structure makes it possible for all users to work in close collaboration.

With the PDT (Project Definition Tool), TSE (Test and Simulation Environment) and MST (Machine Service Tool) tools, robust middleware tailored to suit mobile machinery (MATCH Core), extensively tested library modules and an open standard IDE, you can develop and maintain your control systems consistently across their entire lifecycle.

Based on the V-model, with consistent data, integrated safety standards and time savings of up to 50%.

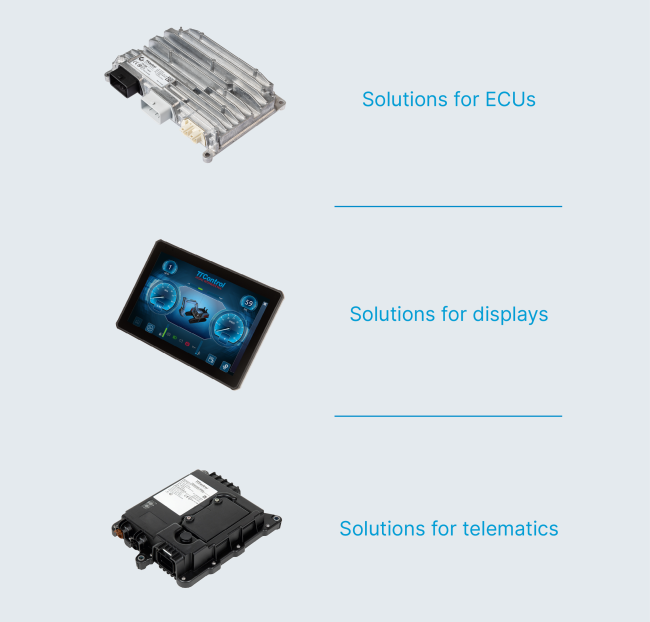

TTControl products with MATCH

- ECUs

- Standardized programming interface provided via embedded core software

- ݀Optimized and extensively tested software solutions in ‘C‘ are used to program the embedded controllers

- ݀Modules are TÜV-certified according to IEC 61508, ISO 13849, ISO 25119, ISO 19014, ISO 26262

- Displays

- MATCH provides comprehensive libraries for display visualization solutions according to Qt and CODESYS

- MATCH enables remote access to machine data via CAN, WLAN or through standard mobile communication interfaces

MATCH Packages

There are six modular software packages that build upon each other. Each software package covers different levels of complexity and work tasks.

The main highlight is that each software package can be extended with additional software tools and/or add-ons for the tools, allowing you to cover all your machine control’s specific requirements with pinpoint accuracy.

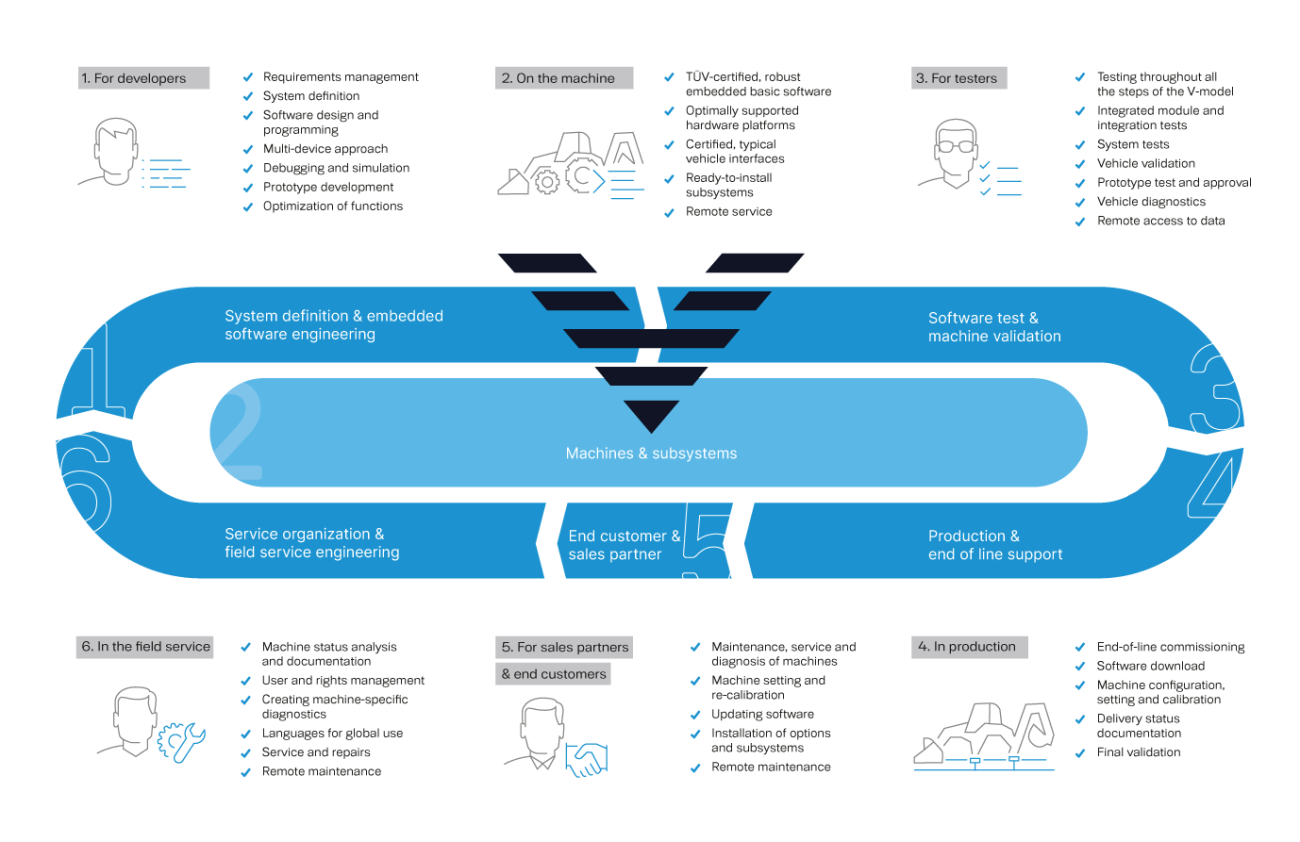

MATCH Tool Chain

The MATCH tool chain is made up of optimally coordinated tools. The consistent structure makes it possible for all users to work in close collaboration.

With the PDT (Project Definition Tool), TSE (Test and Simulation Environment) and MST (Machine Service Tool) tools, robust middleware tailored to suit mobile machinery (MATCH Core), extensively tested library modules and an open standard IDE, you can develop and maintain your control systems consistently across their entire lifecycle.

Based on the V-model, with consistent data, integrated safety standards and time savings of up to 50%.