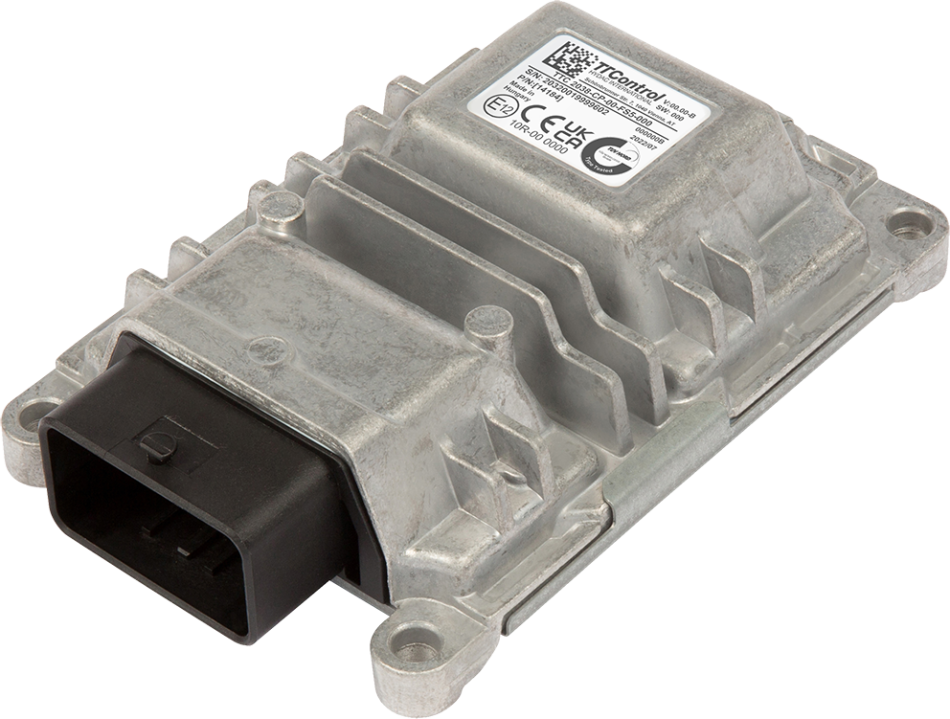

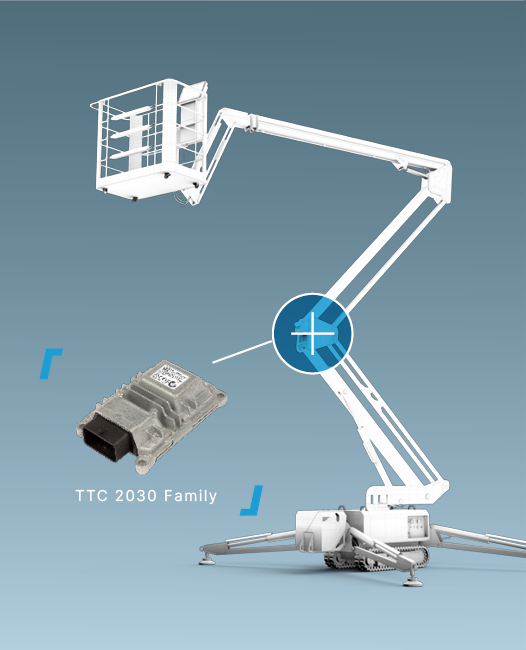

The TTC 2030 product family includes the compact safety-certified TTC 2038 electronic control unit and the CANopen® safety certified I/O module TTC 2038XS. The compact and flexible product family is the perfect fit for small vehicles and applications. The products are sharing modularity and synergy potential with the TTC 2000 series which ensures significantly reduced development efforts and fast time to market for OEMs of mobile machinery.

Optimized performance for mobile applications

The TTC 2030 family is equipped with Infineon’s second-generation AurixTM CPU. The two lockstep cores running at 300 MHz provide the right performance for various off-highway applications and enable future proof vehicle architectures.

Cybersecurity is very important for mobile machinery, to ensure safe, uninterrupted operation and avoid unauthorized access to data or denial-of-service attacks. We offer a cybersecurity package for all ECUs in the TTC 2000 series – check out the flyer below.

Our starter kits provide you with a hands-on experience. Don’t just think about using our ECUs in your project, simply try it out. Dive into a world of possibilities with all the components and guidance that you need. Unbox our starter kits and witness firsthand the unmatched performance and unparalleled reliability of our products.

Safety-certification and mixed-criticality

The TTC 2030 family is safety-certified according to various safety standards:

- SIL 2 and PL d certified for machinery (IEC 61508 / EN ISO 13849)

- for the agricultural market according to AgPL d (ISO 25119)

- for earth-moving machinery according to MPL d (ISO 19014)

- ASIL C certified for cars, trucks, and buses (ISO 26262).

The products are certified by TÜV Nord. The mixed criticality concept of the TTC 2030 family, also known as freedom from interference, allows both safety-related and non-safety-related code to be executed on the same AurixTM CPU without reducing the overall safety level. This leads to significantly reduced time–to-market of mobile machinery.

Highly configurable inputs and outputs

The TTC 2030 variants are equipped with up to 32 inputs and outputs (I/O). The I/Os are highly configurable for different types of sensors and actuators. This makes the TTC 2030 product family the perfect fit for compact applications. Part of the I/O set are analog and digital timer inputs, both high-side and low-side PWM outputs, as well as PVG control outputs. The controllers are designed for a total load current of up to 24A and high inrush currents.

Large set of interfaces for future proof vehicle architectures

The TTC 2030’s modern communication interfaces address the enhancing requirements of electronic architectures in tomorrow’s smart off-highway vehicles. For connection of smart sensors, up to four SENT interfaces, including the Short PWM Code (SPC) enhancement, are available. The TTC 2030 ECU product family is furthermore equipped with a LIN interface and two CAN-FD interfaces with up to two Mbit/s. One CAN channel can be used as wake-up source. In cases of agricultural use, an ISOBUS compliant CAN bus is available.

Operating system and efficient programming

Part of the software package delivered with the TTC 2030 is the real-time operating system PXROS, which is also safety certified. It enables free distribution of tasks between the two CPU cores for efficient application programming. By sharing modularity with the TTC 2000 series software blocks can be reused between different ECU families. The TTC 2038 can either be programmed in a C/C++ environment or in the future also with CODESYS Safety SIL 2.

The powerful MATCH toolchain by HYDAC is optionally available and provides enhanced functionality for testing and service in the field.

Break-out Boxes

Our break-out boxes simplify commissioning and speed up field diagnostics. They integrate directly into existing cabling with a 1.5 m connection cable. The 4 mm safety lab connectors allow the use of conventional measurement equipment and reduce the risk of short circuits. The short-circuit plug jumper enables simultaneous measurements and manipulations. These boxes are available for various controller sizes. For more information and an overview of all available accessories, visit HYDAC Software.

Enhance this hardware with dedicated software applications. We help OEMs throughout the entire machine development life cycle. Learn more and get in touch with our Application Development Center

Cybersecurity is becoming more important in our interconnected world, also for mobile machinery. TTControl implements cybersecurity measures to help customers protect their machines against unauthorized data access, denial-of-service attacks, and third parties taking control of a unit or the entire vehicle. Learn more on our cybersecurity page.